GV81-THIXOTROPIC

Thixotropic synthetic gypsum

Benefits

- Non-toxic synthetic gypsum with thixotropic characteristics

- Applicable / brushable on walls or ceilings with excellent adhesion of the substrates

- Very high dimensional accuracy and very low expansion level

- High surface hardness with very high tensile and flexural strength

- Pourable at cold without the need of firing with long processing times

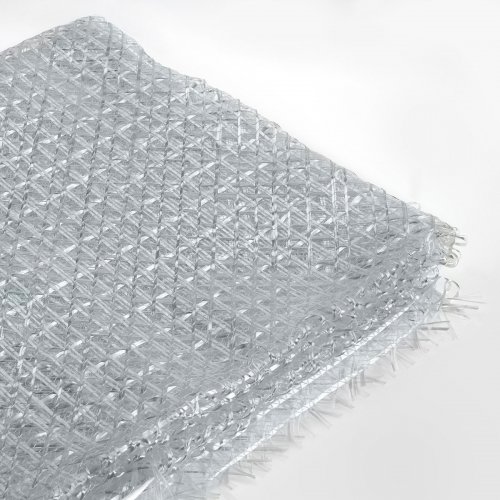

- It must be reinforced with quadriaxial fabric inserts (VV030)

Non-toxic synthetic gypsum in white thixotropic powder. Mixed with water in the correct stoichiometric ratios, it can be perfectly brushed and applied on a wide range of surfaces without the need of firing. Through the use of quadriaxial fiber it is possible to obtain a final product of absolute precision, with perfect replication even of millimeter details and with high mechanical strength. It is also possible to make GV81 pourable through the use of the fluidifying agent AV80-FLUID.

- Non-toxic thixotropic powder with a very high degree of whiteness

- Powder / Water mixing ratio 1: 0.28 in the correct stoichiometric ratios

- Processing time about 25 - 30 minutes

- Solidification point between 55 and 60 minutes

- Surface hardness higher than 300 N / mm2

- Store in closed rooms free of humidity for at least 12 months

Thanks to his characteristics, the product is particularly suitable for the creation of models, counter-molds, negatives (especially in the healthcare furniture sector) or any product subject to considerable mechanical effort and for the creation of scenographies in the cinematographic-theatrical field.

Sprinkle GV81-THIXOTROPIC in water and mix thoroughly (max 150/200 rpm). We recommend applying a release agent on the model, then proceed to apply the compound using a brush. After the operation, place the quadriaxial fiber on the brushed GV81-THIXOTROPIC layer and press lightly. Then proceed to apply, again using a paint brush, a new layer of GV81-THIXOTROPIC. If necessary, this procedure can be repeated several times up to the get the degree of resistance required; for large molds (eg sinks, shower trays, etc.) 8/10 mm thickness is sufficient. Once the material is hardened and laminated, remove from the mold without twisting.

To make GV81-THIXOTROPIC pourable, mix the GV81-THIXOTROPIC powder with 1-2% of AV80-FLUID fluidifying powder.

GV81-THIXOTROPIC is suitable for repairs and subsequent modifications. To achieve good adhesion, the surfaces of the mold must be roughened with coarse sandpaper and moistened with water. Apply GV81-THIXOTROPIC within the specified processing times. During the hardening phase, the excess material can be roughed up. Once hardened, the product can be sanded, processed and milled.